Steam Stripping Systems

High-Efficiency Removal of Organics and Dissolved Gases

Steam stripping is a highly effective process used to remove volatile organics and dissolved gases from wastewater. Ideal for handling complex compounds like benzene, ammonia, and toluene, our custom-engineered steam strippers operate at elevated temperatures and pressures to achieve maximum separation efficiency.

Why Choose Steam Strippers?

Steam stripping towers offer significant advantages over traditional air stripping, especially in applications requiring high removal rates or the recovery of valuable organics. Operating at higher temperatures and pressures, these systems maximize separation efficiency and minimize downstream treatment needs.

Steam Strippers are ideal for:

-

High-strength ammonia wastewater treatment

-

Recovery of BTEX compounds (benzene, toluene, ethylbenzene, xylene)

-

Petrochemical and refining applications

-

Chlorinated hydrocarbon removal

How Do Steam Strippers Work?

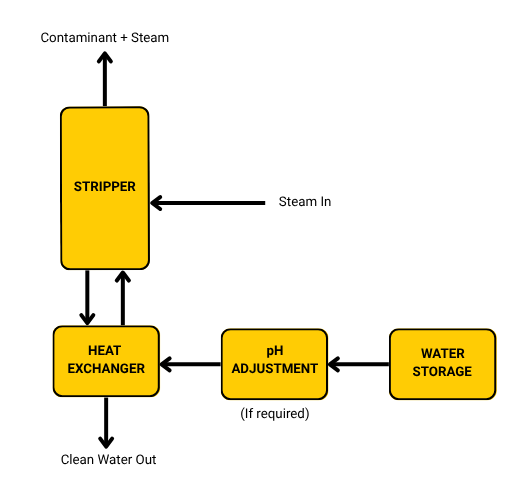

Steam strippers operate using a counter-current flow of steam and water. Steam is introduced at the base of the column, while wastewater enters at the top. As the steam flows upward, it strips volatile compounds from the water, transferring them to the vapor phase. The resulting steam is then condensed, separating the recovered organics or allowing for destruction.

High-Temperature Operation

Steam provides superior stripping efficiency compared to air, particularly for low-volatility compounds or high-concentration waste streams.

Tray Design Over Packing

Due to the high operating pressure and potential fouling, tray columns are favored over packed beds. Trays are easier to clean and maintain, particularly in refinery settings where tars or sticky residues are common.

Condensation & Separation

Stripped vapors are condensed, and the organic phase is separated. Clean water may be refluxed back into the column or discharged.

Key Features of Steam Strippers

Our steam strippers are engineered for durability and precision. Every component is built to withstand high pressure and temperature operating conditions.

-

Alloy Construction Options

Designed using carbon steel, duplex stainless steel, or alloy materials, depending on oxygen exposure and corrosion risk.

-

ASME Code Compliance

Built to ASME Section VIII Div 1, API standards, or TEMA as needed.

-

Customized Integration

We can provide a complete, comprehensive system or incorporate components into existing systems. Includes stripper column, steam heat exchangers, pumps, controls, and optional condensation recovery systems.

-

Modular Design

Scalable to your flow rate and treatment goals.

At Branch Environmental, we custom design and engineer systems with your goals in mind.

Guaranteed Performance Tailored To Your Application

Various Material Options For Any Operating Condition

Complete Packages Including: Controls, Fans, Pumps & More

Scalable Designs To Fit Your Manufacturing Needs

Let's Work Together

At Branch Environmental, we provide comprehensive steam stripping systems for industrial water and wastewater treatment. Contact us today to discuss your application and discover how a steam stripper can optimize your operation.