H₂S Strippers

Targeted Hydrogen Sulfide Removal from Water

Branch Environmental custom-engineers H₂S Strippers to eliminate hydrogen sulfide (H₂S) from wastewater and process streams. These systems use air stripping to ensure safe, odor-free discharge and environmental compliance.

Why Choose H₂S Strippers?

Hydrogen sulfide is a toxic, odorous gas that must be removed efficiently from water streams to meet regulatory standards and avoid corrosion, odor complaints, and downstream treatment issues.

Our H₂S strippers use air or natural gas as the stripping medium and are tailored to match your target pH, temperature, and treatment goals. From municipal wastewater plants to industrial sites, MXD delivers fully integrated solutions built for durability and precision.

Common Applications Include:

-

Wastewater treatment (municipal & industrial)

-

Groundwater remediation

-

Odor control at lift stations and lagoons

-

Process water conditioning

-

Biogas desulfurization (when integrated with flares or oxidizers)

How Do H₂S Strippers Work?

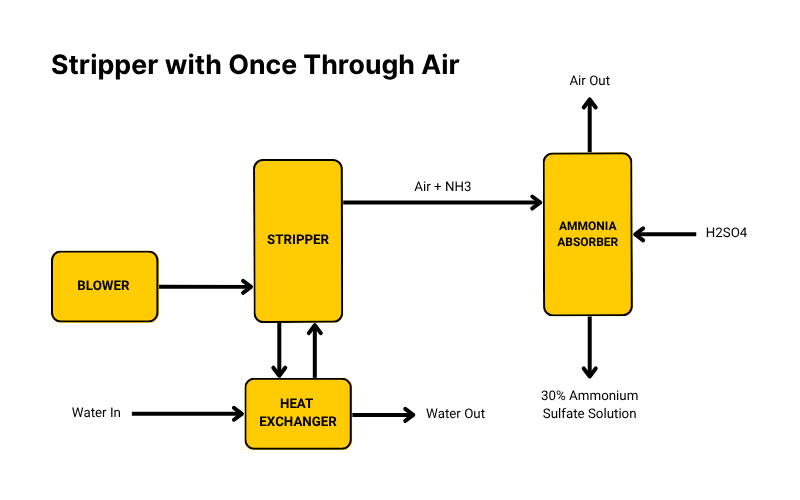

The system operates on air stripping principles, where contaminated water flows downward through a packed column while air or gas moves upward in a counter-current configuration.

Chemical Conversion

At pH levels between 4–5, soluble sulfides are converted into volatile H₂S gas. This transformation enhances stripping efficiency, allowing the gas to transfer from the water into the air stream.

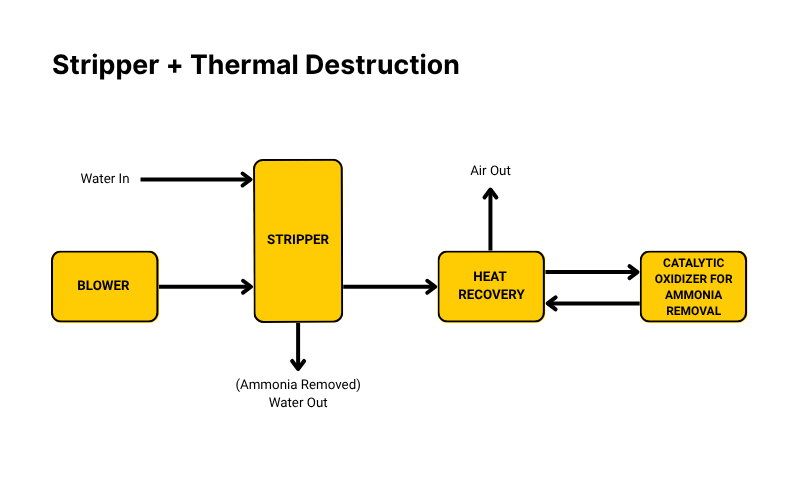

Optional Air Treatment

In low-concentration applications, H₂S can often be vented safely. For higher concentrations or odor-sensitive environments, the air stream is routed to a secondary treatment step—such as a chemical scrubber or thermal oxidizer—where the gas is neutralized into an inert compound like sodium sulfate or fully destroyed.

Key Features of H₂S Strippers

Our H₂S strippers are built to handle a wide range of water chemistries and operating environments, with options to suit treatment goals, emissions regulations, and site limitations.

-

Flexible Media Options

Choose from random or structured packing to optimize contact efficiency for your specific contaminant load and operating conditions.

-

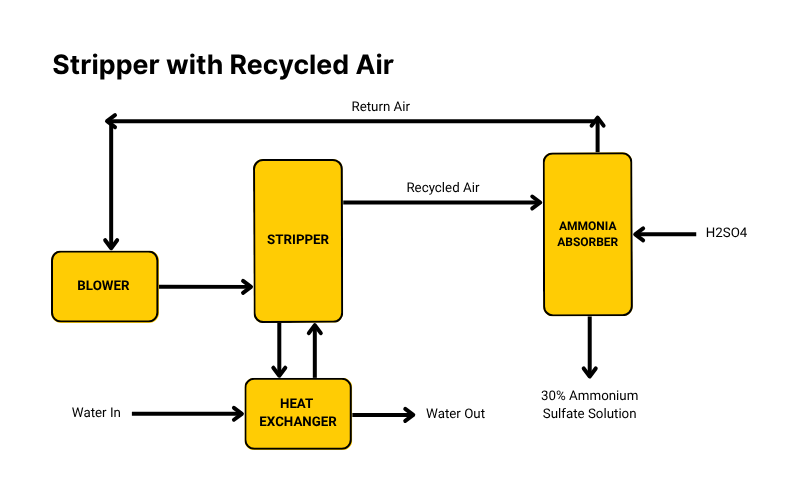

Closed-Loop Designs Available

Minimize emissions and increase efficiency with fully integrated absorber loops for air recirculation.

-

Compatible With Scrubbers or Oxidizers

Easily pair with our chemical scrubbers or catalytic oxidizers for complete VOC and H₂S destruction.

-

Multiple Construction Materials

Available in fiberglass for corrosive wastewater or carbon steel for natural gas stripping. ASME-rated options available.

-

Scalable Systems

From compact single units to high-flow custom configurations (up to 3000 GPM), we engineer to your specs.

At Branch Environmental, we custom design and engineer systems with your goals in mind.

Guaranteed Performance Tailored To Your Application

Various Material Options For Any Operating Condition

Complete Packages Including: Controls, Fans, Pumps & More

Scalable Designs To Fit Your Manufacturing Needs

Let's Work Together

At Branch Environmental, we deliver more than just hardware—we engineer complete environmental solutions. From stand-alone H₂S strippers to systems integrated with oxidation or scrubbing stages, our team will help you meet air and water quality goals without overengineering or overspending.