Ammonia Strippers

Ammonia Removal Through Air Stripping

Our ammonia stripper systems are engineered to deliver high-efficiency removal of ammonia from industrial wastewater. Through pH and temperature adjustments, volatile ammonia is stripped from the water and managed using various discharge options to meet regulatory and environmental requirements.

%20(1).png?width=500&height=500&name=AI%20Graphics%20-%20Branch%20-%20MXD%20Process%20(2)%20(1).png)

Why Use Air Strippers for Ammonia?

Ammonia strippers use a packed tower design to create optimal contact between contaminated water and upward-flowing air. The system operates by adjusting pH and temperature to convert dissolved ammonium ions into free ammonia gas, which is then removed from the liquid phase through air stripping.

Key applications include:

- Industrial wastewater treatment

- Municipal water facilities

- Agricultural runoff management

How Do Ammonia Strippers Work?

The system relies on the natural chemical equilibrium between ammonium ions and ammonia gas:

- At high pH (typically 9.5 to 12), ammonia shifts to a gaseous state.

- Heated water (up to 120°F) accelerates volatilization.

- Air blown from the base of the tower passes upward through packing media.

- As water flows down the column, gaseous ammonia transfers into the air stream.

The result is purified water and air containing volatilized ammonia.

Optimizing Stripper Performance

Our systems are designed with precise control over:

-

pH levels

-

Water temperature

-

Air-to-water ratio

-

Packed bed height

These variables directly impact removal efficiency, which can reach up to 90% with properly configured units.

Options for Ammonia Management

After ammonia is transferred to the air stream, there are three main handling options:

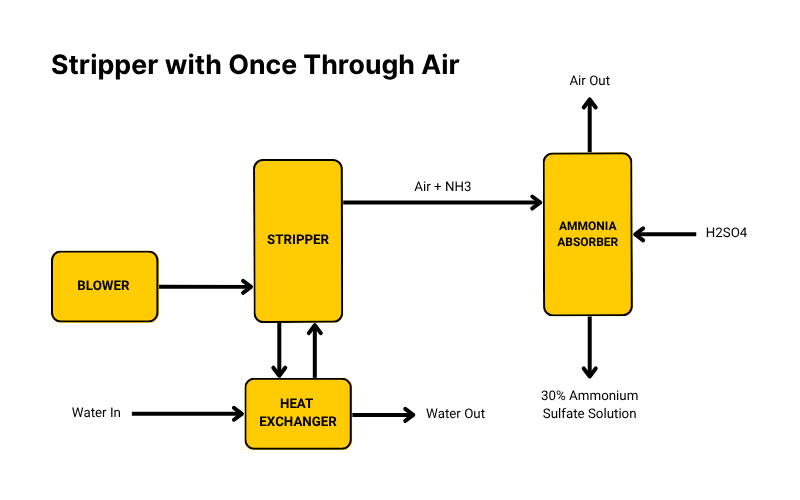

Air Dispersal

-

Discharges stripped air directly to the atmosphere.

-

Suitable for small systems or regions with minimal regulation.

-

Lowest initial and operating cost.

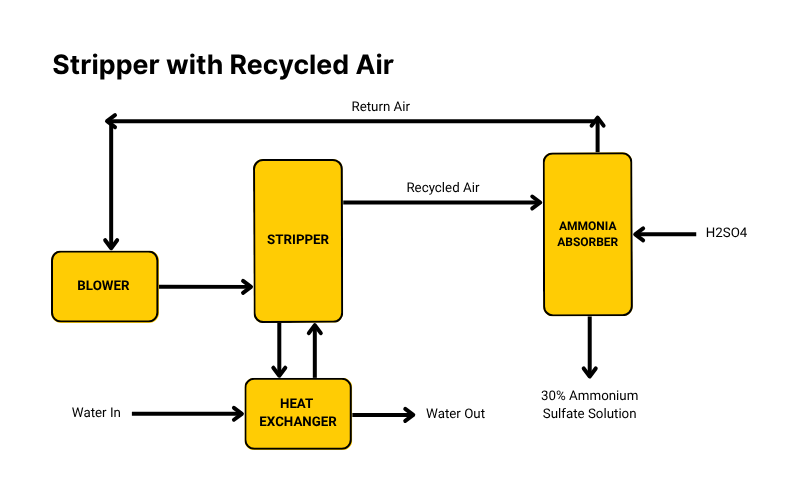

Closed Loop Systems

-

Uses acid wash absorbers to convert ammonia to ammonium sulfate.

-

Recirculates air through the system, minimizing emissions.

-

Ideal when zero air discharge is required.

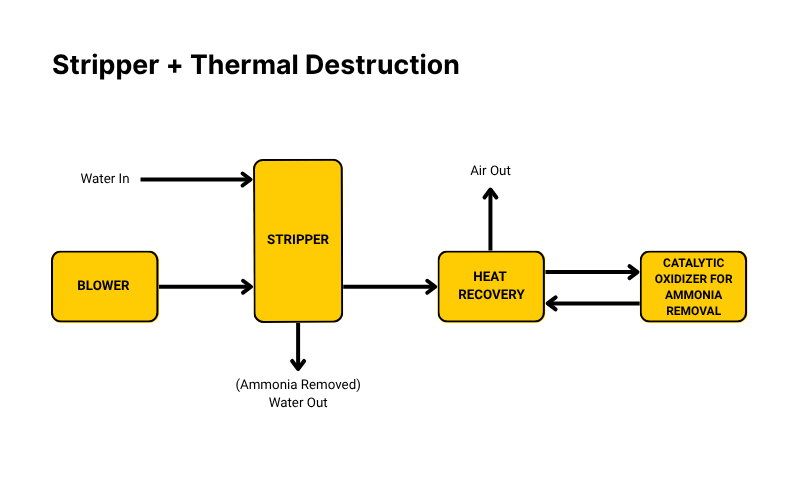

Catalytic Oxidation

-

Burns ammonia at ~550°F over a catalyst, converting it to nitrogen and water vapor.

-

Produces clean exhaust with no ammonia or sulfate byproducts.

-

Excellent for strict emission control environments.

Key Features of Ammonia Strippers

Our ammonia strippers are built for high efficiency and long-term durability in demanding industrial water treatment settings. Every unit is carefully engineered to ensure reliable ammonia removal through optimized stripping performance, robust materials, and flexible design options tailored to your specific pH, temperature, and air-to-water ratio requirements.

-

High Removal Efficiency

Our systems achieve up to 90% removal rates by optimizing pH, temperature, and air contact.

-

Flexible Operating Conditions

Designs support a range of flow rates, pH levels, and temperatures—including ambient and heated water.

-

Custom Configurations

Available in single or multi-stage towers. Capacities up to 3,000 GPM.

-

Complete Turnkey Solutions

We provide entire packages including control systems, blowers, pumps, and optional post-treatment systems like absorbers or oxidizers.

-

Built to Last

Constructed from fiberglass, stainless steel, and other durable materials for long service life.

At Branch Environmental, we custom design and engineer systems with your goals in mind.

Guaranteed Performance Tailored To Your Application

Various Material Options For Any Operating Condition

Complete Packages Including: Controls, Fans, Pumps & More

Scalable Designs To Fit Your Manufacturing Needs

Let's Work Together

At Branch Environmental, we design ammonia stripping systems tailored to your specific discharge requirements, flow rates, and ammonia concentrations. Contact us today to learn how we can support your wastewater treatment goals.