Air Strippers

Water Purification & VOC Removal

Efficiently remove volatile organic compounds, ammonia, hydrogen sulfide, and other dissolved gases from water with MXD Process Air Strippers. Our systems ensure clean water output while minimizing energy consumption and air handling costs.

Why Choose Air Strippers?

Air Strippers are a proven technology for the removal of VOCs and other volatile contaminants from water. Our counterflow column designs maximize contaminant removal while minimizing the volume of air required for treatment—reducing the need for costly downstream air handling systems. Whether you’re treating groundwater, industrial process water, or wastewater streams, MXD Process delivers engineered solutions for efficient and reliable water purification.

How Do Air Strippers Work?

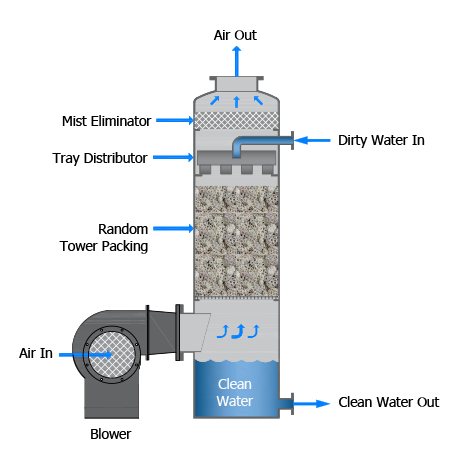

At the heart of our system is a counter-current flow design. Contaminated water flows downward while ambient air flows upward through the column. This process leverages the volatility of contaminants, allowing them to transfer from the water phase into the air phase, leaving purified water behind.

For higher removal efficiencies or less volatile compounds, systems can be equipped for heated operation or steam stripping.

Applications

- Groundwater Remediation

- Industrial Wastewater Treatment

- Process Water Purification

- Removal of VOCs, Ammonia, Hydrogen Sulfide, and Carbon Dioxide

Key Features of Air Strippers

Our scrubbing towers are engineered with a focus on durability and precision. The construction emphasizes components and materials that stand up to harsh industrial environments.

-

High Removal Efficiencies

Achieve removal rates of up to 99% for contaminants like ammonia, hydrogen sulfide, and VOCs with properly selected air-to-water flow ratios.

-

Compact & Modular Design

Our systems are designed for easy installation and scalability, with compact footprints to fit tight industrial spaces.

-

Complete System Solutions

From low-pressure blowers to optional vapor phase carbon or thermal oxidation systems, we deliver complete engineered packages.

-

Durable Construction Materials

Constructed with corrosion-resistant materials to withstand harsh operating environments and ensure long service life.

-

Energy Efficient Operation

Low air volume requirements reduce energy consumption and minimize the need for costly post-treatment of exhaust air.

At Branch Environmental, we custom design and engineer systems with your goals in mind.

Guaranteed Performance Tailored To Your Application

Various Material Options For Any Operating Condition

Complete Packages Including: Controls, Fans, Pumps & More

Scalable Designs To Fit Your Manufacturing Needs

Let's Work Together

At Branch Environmental, we design fully integrated air stripping solutions tailored to your specific process requirements. Contact us today to discuss how we can help you achieve compliance and improve operational efficiency.