Selective Catalytic Reduction

Advanced NOₓ Removal for High-Temperature Applications

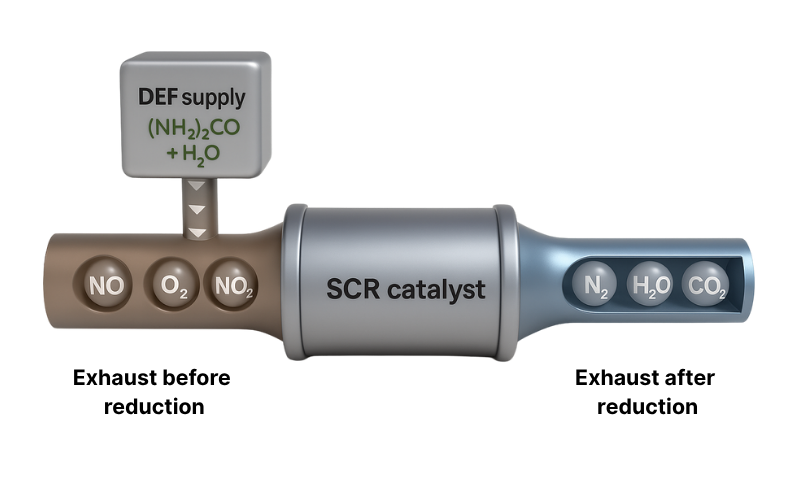

Designed for high-temperature operations, SCR systems use ammonia or urea injection and a specialized catalyst to convert harmful NO and NO₂ into harmless nitrogen and water vapor—without the formation of byproducts like N₂O or excess NOₓ.

Why Choose SCR Technology?

SCR offers significant advantages over traditional scrubbing methods, especially when dealing with high-temperature or low-solubility gas streams. Scrubbing NOₓ is difficult and costly due to poor solubility in water and unwanted byproduct formation. SCR provides a clean, dry, and highly efficient alternative—making it ideal for everything from boilers and gas turbines to nitric acid processes.

Applications:

- Flue gas treatment from incinerators, kilns, boilers, and turbines

- Chemical processing involving nitric acid or ammonia

- Processes requiring high-efficiency NOₓ reduction without wet scrubbing

How Does SCR Work?

In a typical SCR system, a reduced nitrogen compound—ammonia (gas or liquid) or urea—is injected into the process gas stream. This gas mixture then flows over a catalyst that accelerates the reaction, converting NO and NO₂ into nitrogen and water:

Ammonia Reaction

NH₃ + NOₓ + O₂ → N₂ + H₂O + CO₂

Urea Reaction

(NH₂)₂CO → NH₃ + HNCO

HNCO + NOₓ + O₂ → N₂ + H₂O + CO₂

Optimized Performance Across a Wide Temperature Range

The catalyst enables these reactions at temperatures between 500°F and 1000°F (260–530°C) depending on the formulation. Special configurations like ceramic honeycomb substrates are used to minimize pressure drop and facilitate replacement.

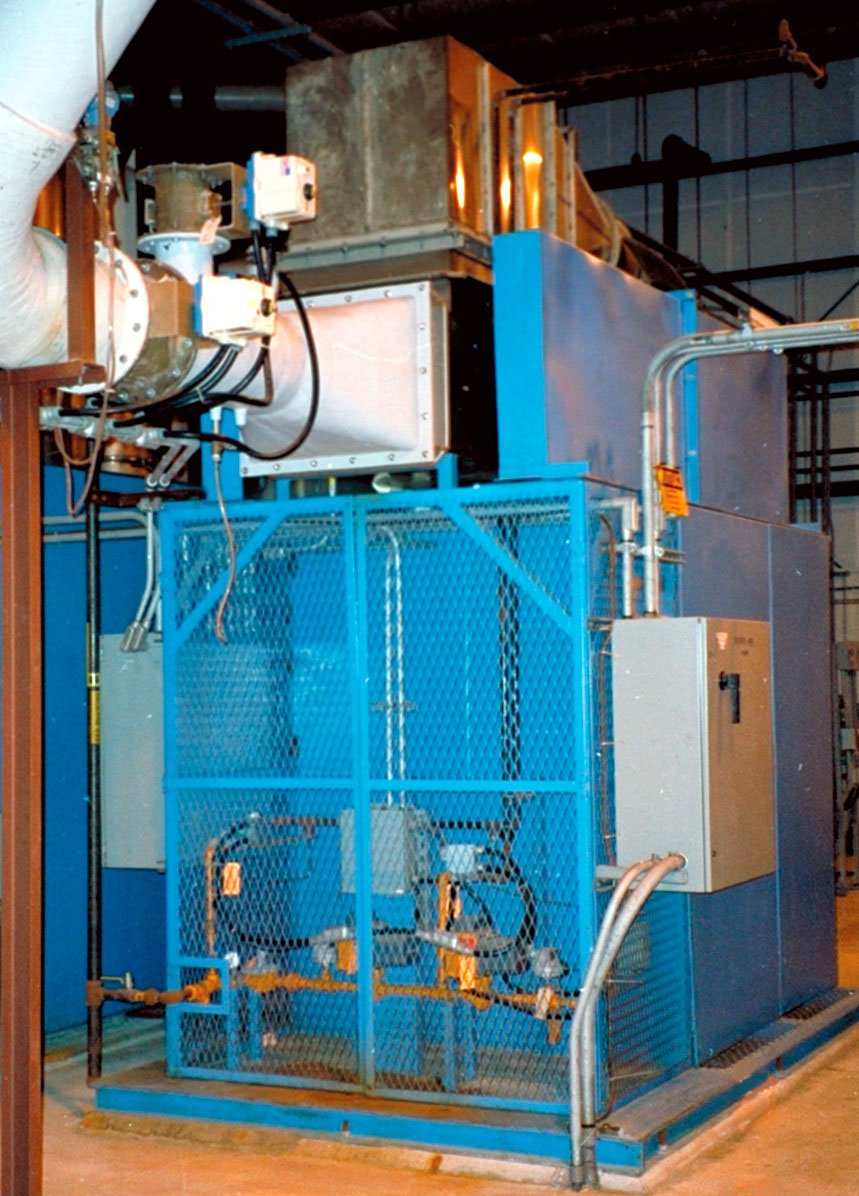

Key Features of MXD SCR Systems

-

Flexible Ammonia Delivery

Supports gas-phase ammonia, aqueous ammonia, or urea injection depending on safety, efficiency, and availability.

-

Catalyst Versatility

Choose from ceramic monoliths, honeycomb substrates, or packed beds—optimized for your operating temperature and chemistry.

-

Guaranteed Efficiency

Standard systems achieve 80–85% NOₓ removal; higher performance is available with added catalyst volume or heat management.

-

Integrated Heat Recovery

Preheat ambient or low-temp gas streams using exhaust energy to reduce fuel costs and increase system efficiency.

-

Material Options for Harsh Conditions

Available in stainless steel, fiberglass, or specialty alloys to suit corrosive or high-heat environments.

-

Smart System Design

We model thermal loads, temperature rise, and flow dynamics to protect catalyst life and meet emission targets.

At Branch Environmental, we custom design and engineer systems with your goals in mind.

Guaranteed Performance Tailored To Your Application

Various Material Options For Any Operating Condition

Complete Packages Including: Controls, Fans, Pumps & More

Scalable Designs To Fit Your Manufacturing Needs

Let’s Build the Right System for You

Not sure if SCR is the best fit? Our engineers will evaluate your process to determine whether catalytic reduction or wet scrubbing is the most efficient and cost-effective solution.