Regenerative Thermal Oxidizers

High-Efficiency VOC Destruction with Minimal Fuel Use

Regenerative thermal oxidizers (RTOs) offer maximum efficiency for low-VOC processes by reusing heat through ceramic media, cutting fuel use while ensuring high pollutant destruction.

Why Choose Regenerative Thermal Oxidizers?

RTOs are ideal for applications with low VOC concentrations where energy efficiency is critical. They use a series of ceramic heat exchange chambers to retain and reuse heat from the oxidation process. As a result, fuel use is minimized without sacrificing performance—achieving up to 95% thermal efficiency.

These systems are especially effective in:

- Industrial processes with fluctuating VOC levels

- Applications where fuel cost and consumption must be minimized

- Scenarios where high destruction efficiency and stable operation are non-negotiable

How Do Regenerative Thermal Oxidizers Work?

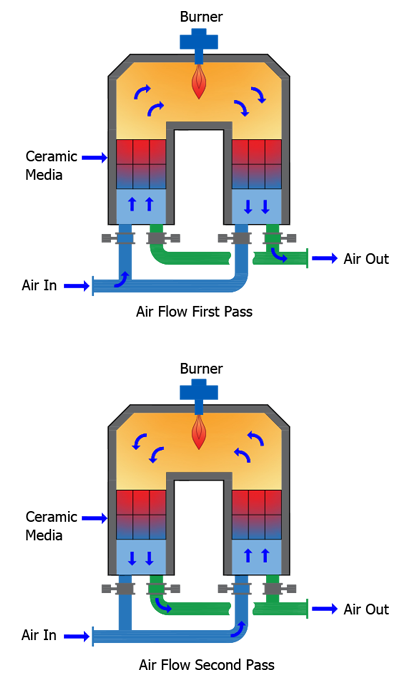

RTOs utilize a multi-chamber design with ceramic media that captures and releases heat during the airflow cycle. Here’s how it works:

1. Preheating Incoming Air

As process gas enters one ceramic media bed, it absorbs heat from the previously treated exhaust stream.

2. Oxidation Chamber

The preheated gas is directed to the combustion chamber, where a burner raises the temperature high enough (typically 1,500°F / 815°C) to oxidize VOCs into carbon dioxide and water vapor.

3. Energy Recovery

Exiting hot gases pass through another ceramic bed, transferring heat to the media before being released. This ensures minimal heat is wasted.

4. Flow Reversal

After a preset time, flow is reversed so that the media beds alternate between heat recovery and gas preheating. This cycling allows the system to maintain thermal efficiency of 80–95%.

Key Features of RTO Systems

-

Durable Media Beds

Choose from honeycomb or random-packed ceramic materials based on your chemical and thermal demands.

-

Multiple Chamber Options

Two-bed, three-bed, and multi-bed configurations available to balance efficiency, VOC load, and process flow.

-

Custom Tailgas Treatment

When oxidizing halogenated compounds or chlorinated VOCs, we offer integrated acid gas scrubbers for full regulatory compliance.

-

Smart Flow Control

Automated flow reversal ensures thermal stability and prevents overheating during high-VOC load conditions.

-

Packaged Systems Available

For emissions that produce secondary contaminants like HCl, we offer integrated RTO + scrubbing systems for complete treatment in a single-source package.

-

Smart System Design

We model thermal loads, temperature rise, and flow dynamics to protect catalyst life and meet emission targets.

At Branch Environmental, we custom design and engineer systems with your goals in mind.

Guaranteed Performance Tailored To Your Application

Various Material Options For Any Operating Condition

Complete Packages Including: Controls, Fans, Pumps & More

Scalable Designs To Fit Your Manufacturing Needs

Let’s Work Together

We design regenerative thermal oxidizers with your operating needs in mind—from energy recovery and chamber configuration to post-treatment scrubbing solutions. Our team offers turnkey systems with guaranteed destruction efficiency, proven thermal performance, and long-term reliability.