Direct Thermal Oxidation

Reliable VOC Destruction & Emission Control

Effectively destroy volatile organic compounds (VOCs) and hazardous air pollutants with our high-efficiency Direct Thermal Oxidizers. Built for simple operation and superior performance.

Why Choose Direct Thermal Oxidizers?

Direct Thermal Oxidizers provide straightforward and reliable VOC destruction by applying high heat to contaminated air streams. Ideal for processes with high solvent concentrations, these systems offer exceptional removal efficiency without the need for complex media or catalysts.

Key Applications

-

VOC & HAP Destruction

-

Chemical & Petrochemical Processing

-

Industrial Manufacturing Facilities

-

Paint, Coating, and Printing Operations

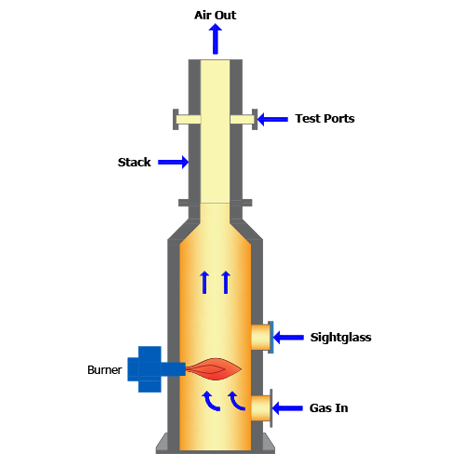

How Do Direct Thermal Oxidizers Work?

At the core of our system is a high-temperature combustion chamber. Process air containing VOCs is heated to temperatures sufficient for oxidation—typically between 1,400°F and 1,800°F. This converts harmful compounds into harmless CO₂ and water vapor, ensuring compliance with environmental regulations.

Thermal Efficiency & Energy Recovery

For improved energy efficiency, our systems can incorporate Air-to-Air Heat Exchangers. These units recover heat from the exhaust gas to preheat the incoming air, significantly reducing fuel consumption and operating costs.

Key Features of Direct Thermal Oxidizers

For improved energy efficiency, our systems can incorporate Air-to-Air Heat Exchangers. These units recover heat from the exhaust gas to preheat the incoming air, significantly reducing fuel consumption and operating costs.

-

High Destruction Efficiency for VOCs and HAPs

Achieve superior removal of volatile organic compounds and hazardous air pollutants, ensuring compliance with strict environmental regulations

-

Air-to-Air Heat Exchangers for Energy Recovery

Reduce fuel consumption and operating costs by recovering heat from exhaust gases to preheat incoming air streams.

-

Compact Footprint for Easy Installation

Space-saving designs allow for easy integration into existing facilities without extensive modifications or downtime.

-

Reliable Operation with Minimal Maintenance

Built with durable materials and simple controls, our systems ensure consistent performance with minimal maintenance requirements.

-

Custom Configurations for Vertical or Horizontal Designs

Designed to fit your unique process layout, our oxidizers can be configured for vertical or horizontal installation to optimize space and performance.

At Branch Environmental, we custom design and engineer systems with your goals in mind.

Guaranteed Performance Tailored To Your Application

Various Material Options For Any Operating Condition

Complete Packages Including: Controls, Fans, Pumps & More

Scalable Designs To Fit Your Manufacturing Needs