Carbon Adsorption Systems

High-Efficiency Air Purification for Industrial Applications

Effectively remove VOCs, hazardous gases, and odorous compounds with our advanced Carbon Adsorption Systems, engineered for maximum contaminant removal and low maintenance operation.

Why Choose Carbon Adsorption Systems?

Carbon Adsorption Systems offer a highly effective solution for vapor phase contaminant removal across a wide range of industrial environments. Utilizing deep-bed designs and advanced carbon media, these systems provide reliable removal of VOCs, ammonia, mercaptans, hydrogen sulfide, and other harmful compounds—making them ideal for both new installations and retrofit projects.

Common applications include:

-

VOC Removal – Capture and remove volatile organic compounds efficiently.

-

Odor Control – Effectively remove hydrogen sulfide, mercaptans, and other odorous compounds.

-

Air Purification – Ideal for ammonia, dioxins, furans, and corrosive gases.

How Do Carbon Adsorption Systems Work?

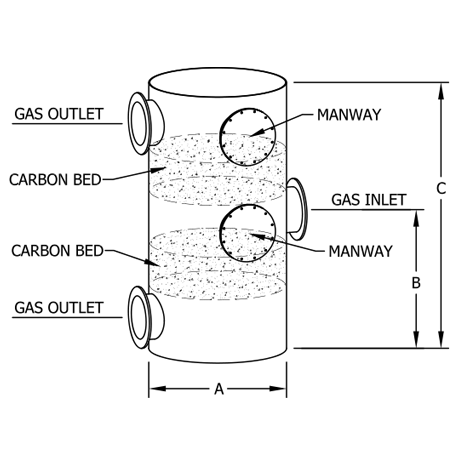

At the core of our systems is a modular deep-bed design featuring corrosion-resistant fiberglass or stainless-steel construction. Contaminated air enters the system and is distributed evenly across selected activated carbon media. As the air stream passes through the carbon beds, harmful gases and vapors are adsorbed onto the carbon surface, ensuring purified air exits the system.

Adsorption Efficiency

The deep-bed configuration maximizes contact time between the air stream and the activated carbon, ensuring high contaminant removal rates—even for low-concentration vapor streams.

Flexible Design

Compact and modular designs allow for easy integration with existing pollution control systems or as stand-alone solutions.

Carbon Media Selection

Various activated carbon types—granular, pelletized, impregnated, and reactivated—are available based on the specific application, ensuring maximum removal efficiency.

Key Features of Carbon Adsorption Systems

Our systems are built with long-lasting materials and designed for performance in demanding industrial environments.

-

Fiberglass or Stainless Steel Construction

Ensures durability and long service life. Construction options are chosen based on the parameters of your environment.

-

Modular Deep-Bed Design

Simplifies installation and maintenance.

-

Multiple Carbon Media Options

Select from a variety of carbon types tailored to your application.

-

High Removal Efficiencies

Achieve up to 99% removal for key contaminants.

-

Compact Footprint

Fits seamlessly into space-constrained facilities.

-

Guaranteed Performance

Backed by our expert engineering support and performance guarantees.

At Branch Environmental, we custom design and engineer systems with your goals in mind.

Guaranteed Performance Tailored To Your Application

Various Material Options For Any Operating Condition

Complete Packages Including: Controls, Fans, Pumps & More

Scalable Designs To Fit Your Manufacturing Needs

Let's Work Together

We don’t just provide Carbon Adsorption Systems - we deliver complete air purification solutions designed to meet your unique operational needs. Contact us today to learn how we can help you improve air quality and meet regulatory compliance with confidence.